Room for optimized processes

With extended assembly halls and a site extension, which will be implemented by the end of 2020, the companies are currently making targeted investments in their future at the Uri site. "On the one hand, we are creating space for optimized processes in order to be able to produce more cost-efficiently and thus better survive in the market," explains Claudia Gisler, who together with her sister Sabine Arnold-Gisler is the owner of the two companies. "On the other hand, by modernizing, we are focusing on careful sustainable growth so that we can maintain our business for the next generation."

Burning, cutting, forming

Within the framework of this future project, the flame cutting and bending center is of particular importance. Twelve employees work shifts in the state-of-the-art production and assembly halls. With an in-house production share of ninety percent, the oxyfuel and plasma cutting systems must offer a high degree of flexibility. Large work pieces with areas of 3,500 mm x 16,000 mm and thicknesses up to 300 mm have to be cut. The demands on shapes and dimensions are very high.

The two existing gantry cutting machines could no longer meet the demand, with their high wearing part costs, too low throughput and ever increasing process uncertainty. New machines and modern digital processes should help to make production more cost-efficient and competitive in the future.

Extensive task definition

In addition to the specifications for the new flame cutting machines to improve quality and throughput, increase process reliability, minimize wear part costs and ensure compatibility of the machines, the innovation plan included high demands on software.

Department Manager of the Flame Cutting and Bending Center Raffael Imgrüt and his team were particularly interested in the user-friendliness of the software, intelligent nesting and the digitalization of order processing. The latter was to be implemented by connecting the existing ERP system. For this purpose, the processes and interfaces were defined in the requirements specification.

Strict selection criteria

When selecting suitable suppliers for this ambitious project, a number of strict criteria had to be met. "The top priority for us was the quality of service support, especially the geographical proximity and the short reaction time of the suppliers," explains Kari Gasser, CEO of Emil Gisler AG. "Direct access to the manufacturer and easy communication are also important to us. Added to this is the conversion of the objective into a task-oriented solution. In addition, we were looking for a solid and innovative supplier", Gasser continues.

Decision for Messer

The decision was made in favor of Messer Eutectic Castolin Switzerland S.A., with its parent company Messer Cutting Systems in Groß-Umstadt, Germany, as the leading global supplier of mechanical engineering technology for the metalworking industry. The range of state-of-the-art cutting systems, flexible service packages and intelligent software solutions exactly matched Gisler's requirements.

Not only is the intensive exchange with customers a priority for the manufacturer the concept of >everything from a single source< offers particular advantages. Messer was able to meet all of Gisler's requirements for machines, software and services.

Versatile cutting systems

With two MultiTherm® flame cutting machines, that support a variety of equipment options, Gisler can now cover a wide range of current and future applications. The versatile cutting machines have been equipped for oxyfuel cutting with one or two ALFA torch heads respectively, as well as one plasma torch each vertically. In this way, they work efficiently and meet the highest demands on quality and productivity. "By using the new machines, we were able to significantly reduce the costs for personnel and wearing parts," says Imgrüt happily. "We have also reduced the proportion of external work with the help of the MultiTherm® machines", continues Imgrüt.

Setting up the software project

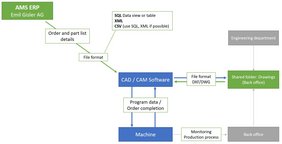

The implementation of the digital processes was a perfect team effort. Peter Maag, Project Manager at Messer Eutectic Castolin, worked with the experts at Messer Cutting Systems and MesserSoft, the software subsidiary of the machine manufacturer, to create an overall solution capable of connecting to existing systems and providing automated feedback of orders.

After that, the interface processes were defined and detailed technical questions were clarified between MesserSoft and the provider of the ERP system AMS. The final concept of the interface programming was made on site in a meeting involving all parties. After the project plan was set-up, MesserSoft started to develop the required interfaces. Once the extensive testing was finished, the software was installed and put into operation.

Task oriented solution

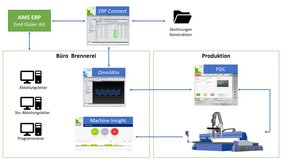

Gisler uses the software suite OmniFab and the CAD/CAM software OmniWin. OmniWin is simple, clear and fast design and nesting software that adapts intelligently to machines and processes. It takes over all cutting tasks for order-based production with CNC thermal cutting machines.

"It was important to us that the systems work hand in hand across the value chain of the company. That's why we chose OmniFab," explains Imgrüt. "Our order data from the ERP system is available in OmniWin. Results from production run back into the ERP system seamlessly together with the order data."

OmniFab is the tool that companies in the flame cutting industry use to drive digital transformation. The OmniFab suite is used for production planning, control and monitoring by >refining< the data. This data adds real value by providing contextual information.

At Gisler, the OmniFab ERP Connect module connects to the AMS ERP system. This enables the automatic exchange of order data from AMS to OmniWin and an automatic import of drawings from the design department. The feedback of production data back to the ERP system is also automated.

OmniFab Production Data Capture (PDC) allows the feedback of production data directly from production back to OmniWin. It achieves this by integrating with the Global Control system connected to the machine. OmniFab PDC generates complete, up-to-date and reliable data in the production control system on set-up, production, loading and unloading times, number of parts produced and scrap.

OmniFab Machine Insight provides the production area with important information about the flame cutting machines during operation. Real-time machine monitoring provides status and data on the connected machines. Information can be seen concerning the program currently being cut on the machine, the current shift, the work in progress, the workload and the number and type of errors that have occurred on the machine.

Knowing what's going on

The introduction of the software ensured maximum transparency in operations management, production planning and control, work preparation, machine operation and service and maintenance at Gisler.

"We now know how things are going in our production and are turning the right screws. Transparency and traceability are the results," says Gasser happily. "We recognize errors faster and initiate measures to eliminate them at an early stage. OmniFab PDC has enabled us to save sixty percent of the workload in order entry and deregistration," adds Imgrüt. The team now always has an overview of all work orders and knows what is pending and what is finished.

Thanks to the automatic import of order data from the ERP system and the simultaneous import of the corresponding drawings from the design department, the manual creation of orders and manual import is no longer necessary. Also the >logoff< has been accelerated considerably.

The machine operators select the nesting plan on the machine in OmniFab PDC and report it as >ready<. Missing parts are recorded directly at the machine and are immediately visible in the nesting plan in OmniWin. The production data of the returned nesting plans are automatically reported to the ERP system, so that here too, no manual intervention is required.

Processes optimized

With the new Messer machines and software, the production department has succeeded in optimizing processes, saving time and taking advantage of the many technical possibilities to increase productivity. Digitization with its automatic data exchange ensures less paper and prevents errors.

For users and machine operators, this means process reliability, up-to-date information in all systems at all times, improved user-friendliness and better workflows.

A look into the future

"We have already taken a big step with the ERP connection and hope for further work simplifying the areas of operating and user tools," summarizes Imgrüt. In addition to the expansion and modernization of the production halls, he and his team are also looking to further optimize and expand contract manufacturing.

When asked about the cooperation with Messer Cutting Systems and MesserSoft, Imgrüt particularly emphasizes the customer-oriented and friendly approach. "We feel the customer orientation," he adds with a smile. The service support, to which the company attaches great importance in terms of location, reaction time and support with the software, is also exemplary. "Definitely yes", they would again opt for this solution.

It is important for the success of such a project to take a close look at the supplier's company structure, in particular its range of products, solutions and broad positioning. Equally important, however, is service friendliness in terms of adaptation to customer requirements, support, maintenance, personal contact and the fast and professional implementation of the solution.

Short profile Emil Gisler AG and GIPO AG

From a small workshop in Seedorf in the canton of Uri in Switzerland, the two worldwide renowned companies Emil Gisler AG and GIPO AG developed since 1973.

Emil Gisler AG provides professional consulting, individual developments and constructions and develops economically cost-effective solutions according to customer requirements. Since 1989, GIPO AG, as a trading company of Emil Gisler AG, distributes the innovative and versatile range of processing systems. Both companies, with their more than 220 employees at the Seedorf site, have repeatedly set standards, especially in the field of mobile crushing. GIPO AG is the only Swiss manufacturer to develop and construct processing units especially for the stone and earth industry and the recycling sector. Today more than a thousand units are in operation worldwide, which are characterized by high-quality components and durability.

Contact:

Raffael Imgrüt

raffael.imgruet@gipo.ch

www.gipo.ch

Short profile Messer Cutting Systems

Messer Cutting Systems is a global supplier of advanced technology. The company offers products and services for the metalworking industry that set standards worldwide. As a pioneer in the industry, the machine builder delivers complete solutions and strategically focuses on customer consulting and customer-oriented innovations. The focus is on the digitalization of processes and products. The company has more than 800 employees at five main locations with production facilities represented in more than 50 countries.

The product range includes oxyfuel, plasma and laser cutting systems, from manually operated machines to special machines for shipbuilding, as well as machines and systems for oxyfuel welding, cutting, soldering and heating. Spare parts, repairs, modernization, maintenance and service as well as environmental technology for the systems complete the program. In-house software solutions optimize production and business processes. The product range is supplemented by solutions from technology partners, for example in the field of automation.

Contact us:

Jörg Ewald

joerg.ewald@messer-cutting.com

www.messer-cutting.com